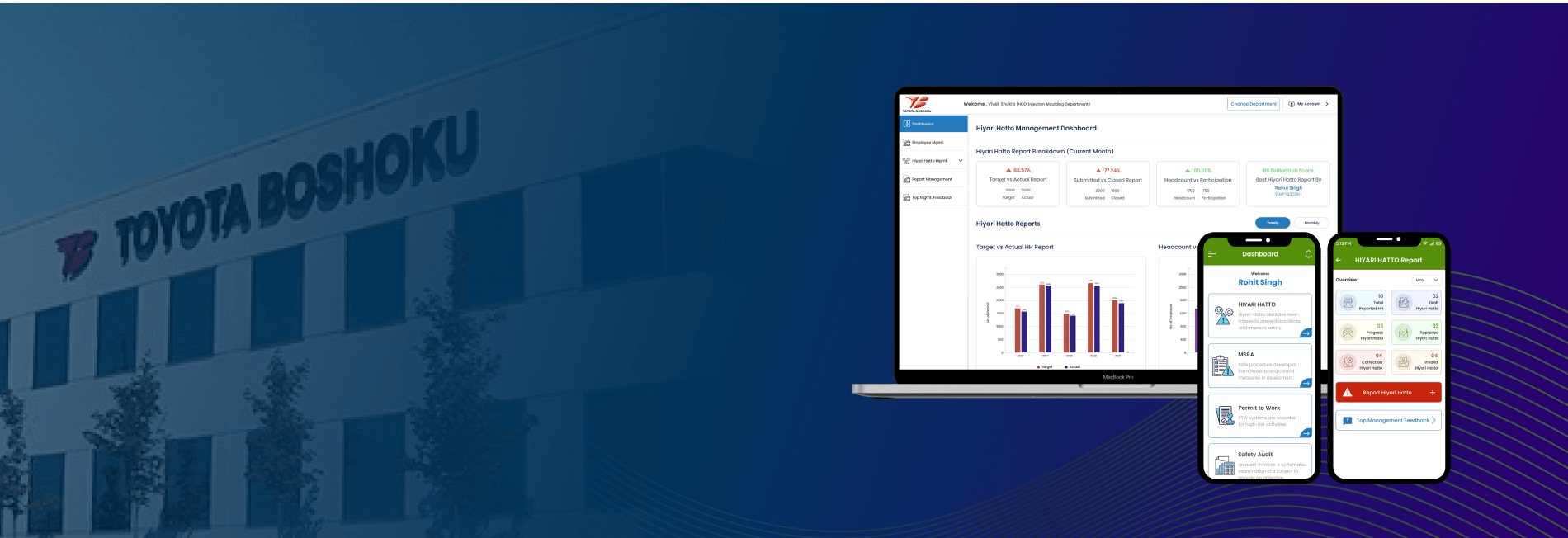

Our Solution

Triazine collaborated with Toyota Boshoku to design and implement a

comprehensive EHS

Management Platform integrating digital workflows for reporting, approvals,

compliance,

and performance analytics. The solution empowered employees, safety champions,

and

leadership with real-time visibility and actionable insights.

Key Business & Technology Initiatives:

Hiyari Hatto (Near-Miss) Reporting Module: Enabled

employees to

digitally record and track near-miss incidents with

multilingual

support (English, Tamil, Kannada, Japanese).

Role-based dashboards for Initiators, Safety Champions,

HODs, and

EHS Admins to manage observations, approvals, and

actions.

Automated approval workflows ensuring quick review,

corrective

measures, and hierarchical escalation.

Geo-tagged corrective actions and photographic evidence

for

closure validation.

Real-time EHS dashboards and analytics to monitor key

metrics —

open incidents, compliance scores, and closure rates.

Best Safety Observation Recognition System to encourage

proactive

participation and safety culture enhancement.

Top Management feedback module establishing two-way

communication

for transparency and continuous learning.

Cloud-based architecture ensuring scalability, high

availability,

and data security across multiple plants.